Archive for category BIM

Work Smarter not Harder? Graphics Standards? Objects? BIM? Building OS

Posted by Jim Foster in architects, BIM, CAD, Standards on July 19, 2011

In a recent article for the IBTimes, David Fano, Practice 2.0: Work Smarter Not Harder, brings up a good point about working together and developing open source systems and standards. He uses creating a national CAD graphics standard as a jumping off point.

In a recent article for the IBTimes, David Fano, Practice 2.0: Work Smarter Not Harder, brings up a good point about working together and developing open source systems and standards. He uses creating a national CAD graphics standard as a jumping off point.

According to the U.S. Bureau of Labor Statistics, architects held about 141,200 jobs in 2008 (source). Hypothetically, if each architect in the U.S. spends 30 minutes a year on average working on standards, as a profession we spend 70,600 hours on standards every year. Just for reference there are 2,080 hours per year in a standard full-time work week (52 weeks x 40 hours). That’s like a firm of 34 full time architects working on nothing but standards every year.

This same thing is happening on a larger scale with BIM. Each camp developing its own standards, objects and regardless of IFC, are not really good at speaking to each other. Even within a BIM platform, such as Revit, you have modelers who will build window families different from each other, now I’m all for artisans, but this seems to be going a bit far. Now if we want to get to a liquid marketplace where each contractor can bid on a building, or component of a building for construction, fabrication or service we need an open platform that everyone can tie into. What we have are ‘readers’ or ‘compilers’ like Navisworks or now BIM Sight from Tekla/Trimble which can suck in disparate information and display it, good, that’s a good step, but you then don’t do ‘something’ in these products and are they added back to the model, it’s another step to update the model with work that might be done, in stead of giving specific permission to a ‘contractor’ to update the model with the work that was done. Perhaps, will have a ton of translators doing the work of minions, but for now there is still a ton of customization, which is good, but without a common standard, a lot of re-work and cross entry and translation (which is bad).

But the short answer to John’s query about an open source approach to the industry, “yeah, right on!”

PointKnown cited in Autodesk Energy Modeling White Paper : BIM

Posted by Jim Foster in 3D, BIM, Built Environment, disto on June 29, 2011

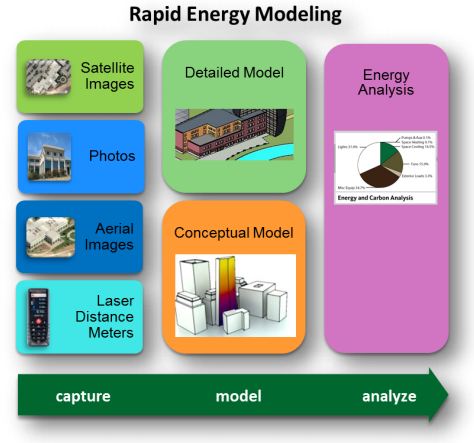

Autodesk has been concentrating on incorporating their energy modeling tools into their workflow, so much so, they are now calling it Rapid Energy Modeling and have outlined a variety of ways to capture a building’s geometry digitally so you can run it through their energy modeling engines. They outlined the following techniques/methods as the most cost effective for capturing exisitng conditions. Full paper available here: rem_white_paper_2011

Autodesk has been concentrating on incorporating their energy modeling tools into their workflow, so much so, they are now calling it Rapid Energy Modeling and have outlined a variety of ways to capture a building’s geometry digitally so you can run it through their energy modeling engines. They outlined the following techniques/methods as the most cost effective for capturing exisitng conditions. Full paper available here: rem_white_paper_2011

Digital photographs

These are photographs of your building taken specifically for rapid energy modeling.

Aerial images

You can download oblique aerial images from Internet sites such as Google Earth or Microsoft®Bing™ mapping services. Alternatively, you can use images from commercial providers of geo-referenced aerial and oblique image libraries such as Pictometry.

Satellite images

Like aerial images, you can download orthogonal images of your building from sites such as Google Earth. RAPID ENERGY MODELING FOR EXISTING BUILDINGS

Laser distance meters

These low-cost laser meters are common surveying tools, and you can also use them onsite to capture key measurements of your building.

PointKnown was cited as the software to use when utilzing laser range finders and capturing a building in revit.

If you plan to capture existing conditions using a laser distance meter, you can use PKNail software from PointKnown (www.pointknown.com) to process those measurements and create a Revit model of your building. By inputting a few simple field measurements PKNail will build a Revit model of the existing structure, in the field, in real time.

This approach involves trained survey personnel that walk around the perimeter of a building and measure key points on the building. The PKNail software utilizes Bluetooth®-enabled laser distance meters to capture dimensional data in the field and send it directly to a laptop loaded with the Revit Architecture or Revit MEP. By capturing data in a specific sequence, the PKNail software creates a Revit model representing the skin of your building as it is being measured.

While we wait for the ‘magic wand’ that digitizes existing buildings while you walk through it, and when I mean digitize, I mean scaled, architectural objects that can be scheduled, processed, etc. more and more technologies are being developed to speed the ‘realty capture’ of buildings. The argument for using PKNail is that the exterior model you build is natively in Revit Architecture and if you want to move inside for interior wall partitioning, etc. for adaptive reuse, etc. you can do that all by utilizing the key pad interface and the laser meter.

Not changing the world just making your day to day a little easier, increase productivity, get more accurate, teeing it up so you can knock it out of the park.

Leica 3D Disto : Capture 3D Points for As Builts and Layouts : BIM

Posted by Jim Foster in 3D, As Builts, BIM, Professional Building Surveyors on June 3, 2011

I cannot pronounce much more than it exists as I have not had my hands on one, and the video included below seems to use it mostly for layouts, not for data capture. NAFTA Leica_3D_Disto_Word-Flyer1.0 . However, when Pointclouds seem excessive from a data and price perspective, and one needs to determine points on inaccessible or complex geometry, this could be the aspirin (does anyone take aspirin anymore) to that headache, or for that matter doing complex ceiling systems or even reflected ceiling.

So what’s on board besides the laser? Camera with 8x Zoom so you can see far off points and DXF input and output and while there is some more stuff that seems to be the most important and data transfer to anything else is via USB stick. Why not include bluetooth as almost every laptop, netbook and the new iPad comes with it and seems a glaring omission. How about if it came with an ‘app’ for iPad and Android instead that could drive instead of its own proprietary piece of hardware.

I wonder if you can move it around in the same room because most rooms I know of are not completely open with shots available to every point you needs, and how you would coordinate points for integrated output? There is some software available called ‘Room Scan’ but have not seen enough of it to know.

MSRP is set at $7995 so up to surveyors, etc to think if it is worth the price tag.

Turner does it. Skanska does it. What about you? Pre Fab Gaining Momentum McGraw Hill Report Shows : Lean BIM

Posted by Jim Foster in BIM on May 16, 2011

One of the latest MCGraw Hill Reports is out, and its got the easy to read melodic title of “Pre-Fabrication and Modularization: Increasing Productivity in the Construction Industry” Now there is a lot of data out there showing that productivity in the Construction Industry has flatlined over the past decades where other industries have seen 200%+ growth. Why? Well I’m no economist but when there was no incentive to change, no economic shock and banks were handing out money to anyone with a pulse, well, why change? Also during this time and still to a degree when you talk about introducing productivity tools/technology to the AEC Industry, in between people laughing at you they’ll say “good luck.” Times are changing though and the report goes on to state that the two main drivers that were driving the increase in PreFab were “increased productivity” and “competitive advantage”, so generally “money” and “close more deals” or in other words, “money”.

So what is this acronymical jargon stew of BIM, Lean, PreFab mean? How about this, spatial coordination/clash detection of “items” built off site to fit together on site like a model (remember attach Part A to Part B) to reduce waste. And waste means everything, time, materials, etc. Turner Construction reported a metal waste average of 15-25% of total recyclable materials with onsite fabrication but with pre fab that dropped to 5-10%. So let’s call that a 50% reduction. 50%, and that’s just in one category.

So is it no wonder that Pre Fab is shown in a glimmering light in this report when one of the sponsors is the Modular Building Institute, well ummn no, but just like if the Milk Board sponsored a study showing that calcium is good for you is that not true? I blogged earlier about Skanska knocking it out of the park using pre-fab on the Miami Hospital so is it no wonder that it is being adopted more rapidly by the rest of the industry. The report also mentions Turner using it because it makes good business sense and when I say that, I mean that from an economic/dollars perspective, less site waste, less time with your crew on site, quicker installs, less wasted time. And what helps enable all this, to make sure it fits the way it is supposed to? BIM, that is Building Information Modeling. So understand there are all flavors of BIM from clash detection, to spatial coordination, etc. it is whatever it is to help you out.

One of the more dramatic benefits of an integrated Lean/ BIM project mindset is that the scales drop from the eyes and we begin to see the waste that is avoided in all its hidden forms: defects, motion, inventory, transportation, overproduction, processing and waiting. By embracing a Lean mindset we are able to deliver efficient, high quality, cost-effective healthcare facilities by capitalizing on the greatest tool we have: human talent. – James P. Barrett | Turner Construction Company | National Director BIM & Lean Building

Hit it hard somewhere.

Trimble offers 59% Premium for Tekla : Hardware meet software : Software meet hardware. : BIM

Posted by Jim Foster in BIM on May 10, 2011

As Scooby would say, “yoinks”. As reported in WSJ and I am sure many other places.

As Scooby would say, “yoinks”. As reported in WSJ and I am sure many other places.

HELSINKI (Dow Jones)–Finnish software company Tekla Corp. (TLA1V.HE) said Monday U.S. Trimble Navigation Ltd. (TRMB) has offered to buy the company for EUR15 a share in cash, a deal potentially worth EUR337 million.

One can see that an integrated hardware/software approach in the building industry could be a true winner. If you talk to people about wanting to introduce technology into the construction trades and what they will say in between the laughing is ‘good luck.’ Easy to use deployable field technologies just don’t exist as they should, Trimble with their know how acquiring Tekla seems like a no brainer as when I first got into this biz, the one product that came up time and time again, before anyone mentioned BIM was that people were using Tekla from design to fabrication because it worked. Recently Tekla announced their own flavors for BIM and 2D drafting, now being able to integrate those tools with the knowledge/expertise or even the combined sales force of Trimble, well, it starts to make a compelling argument. Queen to Bishop 7, Autodesk what’s your next move.

“Owners have to be willing to spend more upfront” : Suffolk saves over $800K on one project. #BIM #Revit

Posted by Jim Foster in BIM, Uncategorized on May 2, 2011

Soft costs. Used to be that 20% of any one project was the yardstick for soft costs, design, engineering, etc. And it always seemed like it was the money that owners/developers loathe to spend. Think about it ‘soft costs’ even the term makes you want to get rid of it or squash it. But we are getting closer to full BIM embrace and a recent post on the Building Design Construction Web Site which highlighted some of Suffolk Construction’s experience using BIM. Says Peter Campot, President of the Healthcare/Science and Technology division of New England’s Suffolk Construction

Soft costs. Used to be that 20% of any one project was the yardstick for soft costs, design, engineering, etc. And it always seemed like it was the money that owners/developers loathe to spend. Think about it ‘soft costs’ even the term makes you want to get rid of it or squash it. But we are getting closer to full BIM embrace and a recent post on the Building Design Construction Web Site which highlighted some of Suffolk Construction’s experience using BIM. Says Peter Campot, President of the Healthcare/Science and Technology division of New England’s Suffolk Construction

We need to transition from design as you go to a design and construction process. We reinvent the wheel everyday right now. Would you ride in an airplane that was a prototype? Buildings are the same way, each is a one-off, but if you build it virtually you’ll build it right. Value-engineering, I would argue, is neither. If we get the construction model right there ARE no RFIs. Higher quality is what I care about. I’m in a reference business. We need a paradigm shift. We need to restructure and transform the industry. Owners have to be willing to spend more upfront. It does come back to them in the end.

Jeff Yoder’s on his post goes on to state that Suffolk uses BIM on every project over $10M. They use clash detection on every BIM project and recommend full BIM on any project over $50M. They also purchased ipads for all their full time employees and use over 50 BIM related technologies and software.

What would be interesting to know is to see a costs schedule of building the ‘typical’ way and then using virtual construction methods. For example, how much did a fully realized BIM model cost vs. 2D CD (Construction Doc) package, and then see the costs savings layered on top that. Let’s get to apples v. apples, dollars v. dollars comparison, but I can’t believe there is any doubt that BIM saves you money, and maybe owners would be willing to split the difference in ‘savings’ or maybe there is a carrot out there the industry can adopt to share the ‘BIM’ winnings.

UK Hits Pause Button on BIM Roll Out

Posted by Jim Foster in BIM on April 25, 2011

As reported by Barry Sullivan on building.co.uk

Efforts to roll out Building Information Modelling across all public projects have hit an obstacle after a key government report on the effectiveness of the software has been met with a three-month delay. An independent report into the effectiveness of BIM on a number of pilot projects was submitted to the Construction Clients’ Group in March and the government was expected to produce its response that same month. However, sources close to the government said that it was put on hold because of local government elections in May. Paul Morrell, the chief construction advisor, subsequently confirmed to Building that the government response would be released in June.

In other BIM news Trimble joined the BuildingSmart alliance in a push to set standards so developers, manufacturers, etc. can leverage a common BIM thread.

BIM @ The London Olympics

Posted by Jim Foster in BIM on April 15, 2011

Da na, na na na Na, na na (okay that was my best attempt at keystroking the Olympic theme song) also makes me wonder if I can say Olympics without some legal disclaimer. Anyway, BIM is at work with the London Olympics, and not for what you orignally might think, but rather for the engineering and widening the M25 Motorway.

M25 Motorway Project

The M25 motorway that circles London is one of Europe’s busiest highways. In 2009, England’s Highways Agency awarded a US$10 billion contract to the Connect Plus consortium for future development, operation and maintenance of the M25 motorway.

Part of that contract includes widening over 23 miles of the motorway’s northwestern quadrant and 17 miles in the northeast from 3 lanes to 4. Construction commenced in the spring of 2009 and must be completed before the London 2012 Summer Olympics. This requires finishing construction in approximately half the time it typically takes for a project of this scope.

In fact Autodesk, in an Oscar worthy, let’s give awards to ourselves turn, awarded the joint venture of Atkins & Skanska Balfour Beatty a Autodesk BIM Experience Award, while I don’t know if you get a statue of glass obloid sort of thing, what I do know, is you don’t do this for the award, you do this because it makes sense, it saves money, it gets things done, so Kudos to you Atkins & Skanska Balfour Beatty, you real men (& women) of genius.

You can read more about the project here: BIM Motorway Project

In the BIM Room : “Your Chocolate is in my Peanut Butter”

Posted by Jim Foster in BIM on March 4, 2011

So not a lot new here in discussing the use of BIM in the ‘Freedom Tower’ , or Tower 2, or WTC 2. I have mixed emotions using WTC, as I imagine many do when mentioning the World Trade Center but having grown up in Jersey, commuting on the PATH to come out of its bowels and having so many friends working down there, well, mostly, it’ still good to say ‘WTC’ anyway while not much new about using BIM in the project except for the fact that this latest was reported by Fox News of all outlets. So for most of us who troll for information about BIM and its uses in esoteric trade magazines, websites, and blogs the fact that Fox News picks up this BIM thread? That part to me is news.

Quick excerpt from article below. Full Jump Here

Serge Demerjian is a Development Manager for Silverstein Properties, the company building Tower 2.

“This is where the trades come together and work all the mechanical, plumbing, fire protection, electrical systems to make sure that they all fit within the space of the building that’s been designed,” he said.

Before the BIM process, a building has been designed and put on paper. BIM then creates a precise computer animated 3D model of how every part in the building will fit together. The goal? Make sure it will.

The chocolate and peanut butter reference was used by Serge in the article, while it’s “two tastes the taste great together” having them in harmony, now that’s beauty of it, then again, maybe chocolate and peanut butter always taste great together, even if they’re just a mess on the plate that your 2 year old put together, so strike that metaphor with BIM, how about engineered tastiness, all right still working on it. But mainstream media and BIM, now there’s two tastes that taste great together, wondering if BIM is right for you? It is.

So if you wonder if this social media stuff works, if blogging is worth it, well my recent post on the Leica 3D Disto wound up on the Leica shore and John Anderson from Leica GeoSytems was kind enough to answer some of the questions I posed. So those of you who were sitting on the edge of your seat. Here ya go.

So if you wonder if this social media stuff works, if blogging is worth it, well my recent post on the Leica 3D Disto wound up on the Leica shore and John Anderson from Leica GeoSytems was kind enough to answer some of the questions I posed. So those of you who were sitting on the edge of your seat. Here ya go.