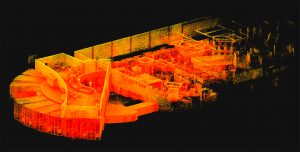

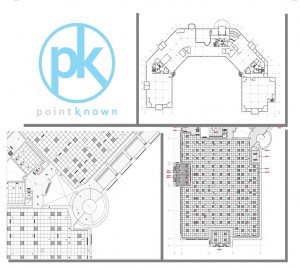

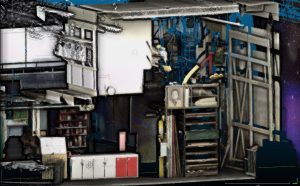

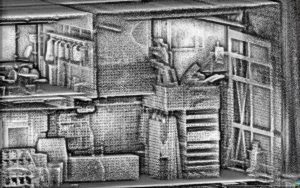

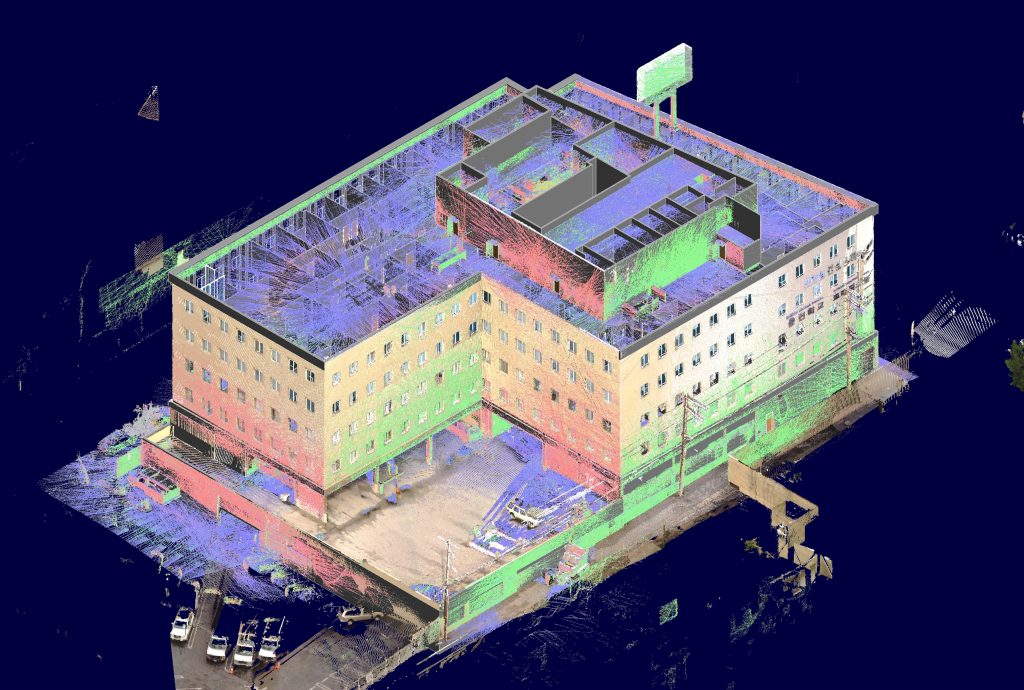

Pointknown tasked with creating a Revit model of an existing YMCA in Santa Ana CA utilized a variety of technologies to capture existing architecture on site. We used a FARO Focus, GeoSlam ZebRevo, Leica Distos and our own PKNail software. And grit, and coffee, and ladders.

Hi Jim, The model is fantastic… 1st Six Words Upon Delivery of our Santa Ana YMCA Revit Model

Troy Fosler – Koning Eizenberg

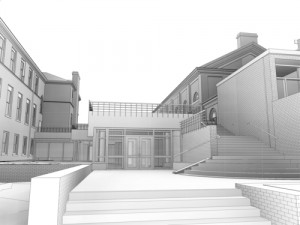

The historic YMCA located in the heart of Santa Ana abandoned over twenty years ago is set to go under a massive rehabilitation and afterwards be returned to the community.

“The proposed renovation of a landmark YMCA built in 1924 will restore the building’s role as a central anchor in the community of Santa Ana. The project aspires to influence positive lifestyles through wellness & fitness programs designed for a variety of local stakeholders.

Having been involved in hundreds of renovation and reuse projects, it’s awesome to be part of one that can have such a huge impact on an entire community. Good on ya Santa Ana I’ll see you in the pool.

.

.